Time: 22, 07 2022 Views: 177

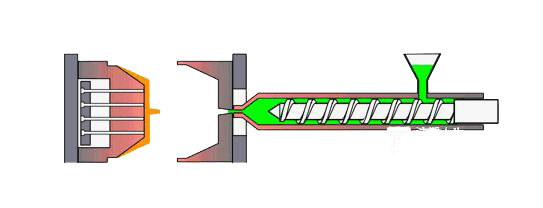

Injection molding machine also known as injection molding machine or injection machine. It is the thermoplastic or thermosetting plastics using plastic molding mold into plastic products of various shapes of the main molding equipment. Divided into vertical, horizontal, full electric. The injection molding machine heats the plastic, applying high pressure to the molten plastic so that it shoots out and fills the mold cavity.

When the injection molding machine is working, the plastic material is injected into the mold cavity through the injection hole according to the established setting procedure, and the mold needs to be rotated. The temperature signal in the mold needs to be transmitted to the control system during injection and cooling, and the real-time monitoring data can ensure the excellent quality of plastic products. In order to realize the power and signal transmission of the mold, the fixed bearing part and the rotating part need to be connected with a conductive slip ring.

In the electromechanical system of injection molding machine, the conductive slip ring also needs to meet the characteristics of high temperature resistance and waterproof.

Parts of the slip ring shell, power cables and signal cables should be protected from being affected in high temperature working conditions. High-precision sealing structure can prevent liquid splashing during processing.

CENO has developed and produced special slip ring for injection molding machine, which not only meets the working conditions of high temperature and water resistance of injection molding machine, but also adopts flat disk structure scheme to save the internal space of the system, and has mature application experience of injection molding machine.